IDEAS,IMPLEMENTATION AND GENERATION

Monday, 6 August 2012

Thursday, 10 May 2012

The Renewable Energy Guide

Introduction to Renewable energy

We all are answerable for climate change and it is our responsibility to work for its solution. In

the past century, it has been noticed that the consumption of non-renewable sources of energy

has caused more environmental damage than any other human activity. Electricity generated

from fossil fuels has led to high concentrations of injurious gases in the atmosphere.

In spite of the harmful effects, the price of the fuels is pushing relentlessly upwards. The reason

is that the demand is exceeding supply by a few million barrels a day and the gap is getting

wider.

The need of the hour is sustainable, clean and green energy. We can no longer afford to spew

out tones of carbon dioxide into the atmosphere, nor can we easily cope with the rising fuel

prices anymore. The myth of inexhaustible natural reserves has been dispelled. We’re

surrounded by many renewable sources of energy, merely waiting to be tapped into.

Renewable energy is the energy derived from natural processes that are replenished frequently.

Renewable sources can avoid above problems by using energy sources that either will last

longer than the human race or can be regenerated. Most renewable energy sources are

environmentally friendly, can fight global warming by reducing carbon emissions and also allow

the economies to lessen their dependencies on politically turbulent nations. Renewable energy

is the energy generated from solar, wind, rain, tides, hydropower, biomass, geothermal

resources, and bio fuels and hydrogen derived from renewable resources.

Different types of renewable energy

Renewable energy is derived from natural processes that are constantly renewed in a short

period of time. Renewable sources of energy differ widely in their cost-effectiveness and their

availability around the world. Though water, wind, and solar may appear free, but their cost

comes in assembling, harnessing, and transporting the energy that could be used. For instance,

to make use of energy from water, a dam with electric generators and transmission lines is

required.

· Renewable energy sources used most often are:

· Solar

· Wind

· Geothermal

· Hydro power

· Biomass

1)SOLAR

Solar:

Solar energy is the cleanest and inexhaustible of all known energy sources. Solar energy is the

light, heat and other radiation that is released from the sun. Solar radiation holds huge amounts

of energy and is responsible for almost all the natural processes on earth.

Science behind the Working of Solar light Panels:

Solar light Panels have photovoltaic cells or Solar Cells which are arranged in a grid-like pattern

on its surface. Solar cells are made of special materials for example silicon. When the solar

energy falls on Solar light Panels, this energy knocks electrons loose and allows them to flow

freely. The solar cells have the electric field that makes the loose electrons to move in certain

direction, which is a current. To take out this current off for external use we place metal

contacts on the top and bottom of our solar cell.

.Different components used to make solar power:

· Solar cells, which are commonly called PV panels

· One or more batteries

· Charge regulator for a stand-alone system

· Inverter, when alternating current (ac) rather than direct current (dc) is required

· Wiring

· Mounting hardware or a framework.

3)WIND:

Wind is a form of solar energy. The irregular heating of the atmosphere by the sun, the

irregularities of the earth's surface, plus rotation of the earth causes winds. This wind energy,

when "harvested" by wind turbines produces energy which can be trapped to generate

electricity and carry out many functions.

Wind energy is generated by the process by which the wind is used to generate mechanical

power or electricity. When wind moves over the turbine blades, it generates a lift. The lift makes

the blades rotate and hence rotate the shaft. The rotating shaft moves a magnetic field in the

generator, which in turn creates electricity

A Wind turbine includes the following parts:

· Gearbox – Gear box connects the low and high-speed shaft to each other

· Blades - wind blowing over the blades causes them to lift and rotate

· Hub - the sphere object used to mount the blades on

· Generator – Generator creates at least 60-cycle AC electricity

· Tower – Tower is the metal pole the turbine operates from. Tower is at least 100 feet

off the ground so that the turbine can capture the least turbulent wind

· Rotor hub – Rotor hub is the hub and the blades together

· Yaw drive – Yaw drive is required only for an upwind turbine; it keeps the rotor facing

the wind

· Yaw motor – It provides power for the yaw drive

· Nacelle – Nacelle sits on top of the tower and clings to the gear box

· Low-speed shaft – It is turned by the rotor at a rate of 30 to 60 rotations every minute

· High-speed shaft – It connects to the generator and drives it

· Anemometer –Anemometer is used to measures the speed of the wind.

3)GEOTHERMAL :

Geothermal

Do you know that Earth’s center can reach 12000 degrees Fahrenheit? Just imagine if we could

tap that heat for our own use. Geothermal systems do just that. Geothermal energy is the

energy that is generated by heat stored beneath the Earth's surface. Geothermal energy taps

the Earth’s internal heat for lot of purposes including electric power production, heating and

cooling of buildings

Three geothermal technologies currently used in the United States are:

· Direct-use systems

· Geothermal power plants

· Geothermal heat pumps

Direct-use systems:

In these systems, a well is drilled into a geothermal reservoir to supply a steady stream of hot

water. The water is brought up from the well, and with the help of piping, a heat exchanger, and

controls the heat is delivered directly for its intended use. A disposal system in some cases

injects the cooled water underground or disposes of it in a surface storage pond. This

Geothermal hot water is used for many purposes including heating buildings, raising plants in

greenhouses, heating water for fish farms, drying crops, or for industrial process.

Geothermal power plants:

In these systems geothermal hot water or steam is used to generate electricity. Older types of

geothermal power plants uses steam from the deep wells to directly drive a turbine to produce

electricity. Nowadays Flash steam plants are the most common type of geothermal power

plants. They use very hot water which is pumped under high pressure to the generation

equipment at the surface. Water is vaporized and the vapor drives turbines to generate

electricity.

Geothermal heat pumps:

Geothermal heat pumps rely on the fact that below the surface, the Earth remains at a relatively

constant temperature all through the year, warmer than the air over it in the winter and cooler

in the summer. This heat pump transfers heat stored in the ground into a building in winter and

it transfers the heat out of the building and back into the ground in summer. The geothermal

heat pump has series of pipes, buried in the ground close to a building to be conditioned. Fluid is

circulated all the way through the pipes to either absorb heat from the ground or distribute heat

to the ground. These Geothermal heat pumps are used for space heating and cooling in

addition to water heating, for residential and commercial applications.

4)Hydroelectric power

The hydroelectric power plants or Dams are used to generate electricity from water on large

scale basis. The hydroelectric power plant is built across the large river which has sufficient

quantity of water. In case the river is large, more than one dam can also be built across the river

but at different locations. Flowing water generates energy which can be captured and turned

into electricity. This is called hydro power or hydroelectric power.

Working or Principle behind Hydroelectric Power Plant:

The water that flows in the river possesses two type of energy: the kinetic energy which is due

to flow of water and potential energy which is due to the height of water.

In hydroelectric power plants potential energy of water is utilized to generate electricity

Water is made to fall with a high force. The force of the water being released through the dam

falls on the blades of turbine, which is turned by the moving water. The shaft from the turbine

goes into the generator, which generates the power. Power lines are linked to the generator

which carries electricity to the homes or factories. When ever the water is done going through

the turbine, the water go back to the river

5)BIOMASS ":

Biomass

The term Biomass often refers to organic material such as timber and crops grown particularly

to be burnt to generate heat and power. Biomass power is power acquired from the energy in

plants and plant-derived resources, such as food crops, grassy and woody plants, remains from

agriculture or forestry, and the organic constituent of municipal and industrial wastes. The highyielding

energy crops like trees and grasses, coupled with high-efficiency conversion

technologies, can supplement our use of fossil fuels and help us take action to global climate

change concerns. Agricultural crops and residues, industrial wood and logging residues, farm

animal wastes, and the organic portion of municipal waste all are biomass feedstock.

We need to make sustainable use of plants or trees as fuel, and replant them as we harvest

them. As long as biomass is produced sustainably by only using as much as is grown—the

battery will last forever. Biofuel technologies can competently transform the energy in biomass

into transportation, heating, and electricity generating fuels.

We all are answerable for climate change and it is our responsibility to work for its solution. In

the past century, it has been noticed that the consumption of non-renewable sources of energy

has caused more environmental damage than any other human activity. Electricity generated

from fossil fuels has led to high concentrations of injurious gases in the atmosphere.

In spite of the harmful effects, the price of the fuels is pushing relentlessly upwards. The reason

is that the demand is exceeding supply by a few million barrels a day and the gap is getting

wider.

The need of the hour is sustainable, clean and green energy. We can no longer afford to spew

out tones of carbon dioxide into the atmosphere, nor can we easily cope with the rising fuel

prices anymore. The myth of inexhaustible natural reserves has been dispelled. We’re

surrounded by many renewable sources of energy, merely waiting to be tapped into.

Renewable energy is the energy derived from natural processes that are replenished frequently.

Renewable sources can avoid above problems by using energy sources that either will last

longer than the human race or can be regenerated. Most renewable energy sources are

environmentally friendly, can fight global warming by reducing carbon emissions and also allow

the economies to lessen their dependencies on politically turbulent nations. Renewable energy

is the energy generated from solar, wind, rain, tides, hydropower, biomass, geothermal

resources, and bio fuels and hydrogen derived from renewable resources.

Different types of renewable energy

Renewable energy is derived from natural processes that are constantly renewed in a short

period of time. Renewable sources of energy differ widely in their cost-effectiveness and their

availability around the world. Though water, wind, and solar may appear free, but their cost

comes in assembling, harnessing, and transporting the energy that could be used. For instance,

to make use of energy from water, a dam with electric generators and transmission lines is

required.

· Renewable energy sources used most often are:

· Solar

· Wind

· Geothermal

· Hydro power

· Biomass

1)SOLAR

Solar:

Solar energy is the cleanest and inexhaustible of all known energy sources. Solar energy is the

light, heat and other radiation that is released from the sun. Solar radiation holds huge amounts

of energy and is responsible for almost all the natural processes on earth.

Science behind the Working of Solar light Panels:

Solar light Panels have photovoltaic cells or Solar Cells which are arranged in a grid-like pattern

on its surface. Solar cells are made of special materials for example silicon. When the solar

energy falls on Solar light Panels, this energy knocks electrons loose and allows them to flow

freely. The solar cells have the electric field that makes the loose electrons to move in certain

direction, which is a current. To take out this current off for external use we place metal

contacts on the top and bottom of our solar cell.

.Different components used to make solar power:

· Solar cells, which are commonly called PV panels

· One or more batteries

· Charge regulator for a stand-alone system

· Inverter, when alternating current (ac) rather than direct current (dc) is required

· Wiring

· Mounting hardware or a framework.

3)WIND:

Wind is a form of solar energy. The irregular heating of the atmosphere by the sun, the

irregularities of the earth's surface, plus rotation of the earth causes winds. This wind energy,

when "harvested" by wind turbines produces energy which can be trapped to generate

electricity and carry out many functions.

Wind energy is generated by the process by which the wind is used to generate mechanical

power or electricity. When wind moves over the turbine blades, it generates a lift. The lift makes

the blades rotate and hence rotate the shaft. The rotating shaft moves a magnetic field in the

generator, which in turn creates electricity

A Wind turbine includes the following parts:

· Gearbox – Gear box connects the low and high-speed shaft to each other

· Blades - wind blowing over the blades causes them to lift and rotate

· Hub - the sphere object used to mount the blades on

· Generator – Generator creates at least 60-cycle AC electricity

· Tower – Tower is the metal pole the turbine operates from. Tower is at least 100 feet

off the ground so that the turbine can capture the least turbulent wind

· Rotor hub – Rotor hub is the hub and the blades together

· Yaw drive – Yaw drive is required only for an upwind turbine; it keeps the rotor facing

the wind

· Yaw motor – It provides power for the yaw drive

· Nacelle – Nacelle sits on top of the tower and clings to the gear box

· Low-speed shaft – It is turned by the rotor at a rate of 30 to 60 rotations every minute

· High-speed shaft – It connects to the generator and drives it

· Anemometer –Anemometer is used to measures the speed of the wind.

3)GEOTHERMAL :

Geothermal

Do you know that Earth’s center can reach 12000 degrees Fahrenheit? Just imagine if we could

tap that heat for our own use. Geothermal systems do just that. Geothermal energy is the

energy that is generated by heat stored beneath the Earth's surface. Geothermal energy taps

the Earth’s internal heat for lot of purposes including electric power production, heating and

cooling of buildings

Three geothermal technologies currently used in the United States are:

· Direct-use systems

· Geothermal power plants

· Geothermal heat pumps

Direct-use systems:

In these systems, a well is drilled into a geothermal reservoir to supply a steady stream of hot

water. The water is brought up from the well, and with the help of piping, a heat exchanger, and

controls the heat is delivered directly for its intended use. A disposal system in some cases

injects the cooled water underground or disposes of it in a surface storage pond. This

Geothermal hot water is used for many purposes including heating buildings, raising plants in

greenhouses, heating water for fish farms, drying crops, or for industrial process.

Geothermal power plants:

In these systems geothermal hot water or steam is used to generate electricity. Older types of

geothermal power plants uses steam from the deep wells to directly drive a turbine to produce

electricity. Nowadays Flash steam plants are the most common type of geothermal power

plants. They use very hot water which is pumped under high pressure to the generation

equipment at the surface. Water is vaporized and the vapor drives turbines to generate

electricity.

Geothermal heat pumps:

Geothermal heat pumps rely on the fact that below the surface, the Earth remains at a relatively

constant temperature all through the year, warmer than the air over it in the winter and cooler

in the summer. This heat pump transfers heat stored in the ground into a building in winter and

it transfers the heat out of the building and back into the ground in summer. The geothermal

heat pump has series of pipes, buried in the ground close to a building to be conditioned. Fluid is

circulated all the way through the pipes to either absorb heat from the ground or distribute heat

to the ground. These Geothermal heat pumps are used for space heating and cooling in

addition to water heating, for residential and commercial applications.

4)Hydroelectric power

The hydroelectric power plants or Dams are used to generate electricity from water on large

scale basis. The hydroelectric power plant is built across the large river which has sufficient

quantity of water. In case the river is large, more than one dam can also be built across the river

but at different locations. Flowing water generates energy which can be captured and turned

into electricity. This is called hydro power or hydroelectric power.

Working or Principle behind Hydroelectric Power Plant:

The water that flows in the river possesses two type of energy: the kinetic energy which is due

to flow of water and potential energy which is due to the height of water.

In hydroelectric power plants potential energy of water is utilized to generate electricity

Water is made to fall with a high force. The force of the water being released through the dam

falls on the blades of turbine, which is turned by the moving water. The shaft from the turbine

goes into the generator, which generates the power. Power lines are linked to the generator

which carries electricity to the homes or factories. When ever the water is done going through

the turbine, the water go back to the river

5)BIOMASS ":

Biomass

The term Biomass often refers to organic material such as timber and crops grown particularly

to be burnt to generate heat and power. Biomass power is power acquired from the energy in

plants and plant-derived resources, such as food crops, grassy and woody plants, remains from

agriculture or forestry, and the organic constituent of municipal and industrial wastes. The highyielding

energy crops like trees and grasses, coupled with high-efficiency conversion

technologies, can supplement our use of fossil fuels and help us take action to global climate

change concerns. Agricultural crops and residues, industrial wood and logging residues, farm

animal wastes, and the organic portion of municipal waste all are biomass feedstock.

We need to make sustainable use of plants or trees as fuel, and replant them as we harvest

them. As long as biomass is produced sustainably by only using as much as is grown—the

battery will last forever. Biofuel technologies can competently transform the energy in biomass

into transportation, heating, and electricity generating fuels.

Sunday, 1 April 2012

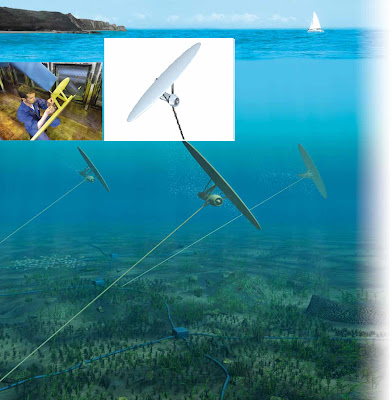

MINESTO TIDAL KITE

Marine energy comes from two main sources:

waves, which originate from wind; and

tides, which are caused by the gravitational

pull of the moon and sun. One of the benefits of

harnessing tidal currents is that, unlike wind and waves,

they are predictable and offer an ecologically friendly

and reliable source of energy.

Minesto has developed a new kind of tidal energy

solution based on its Deep Green concept, which uses

low water speeds to create energy. This revolutionary

concept makes it possible to install and operate plants

in areas where no other known technology can operate

cost effectively, thus expanding the number of sites

where tidal energy can be generated.

A groundbrea king and unique solution

The Deep Green technology converts energy from

tidal stream flows into electricity by way of a novel

principle: an underwater kite. The kite consists of

a wing, turbine and generator, and is attached by

a tether to a fixed point on the ocean bed. The speed

of the kite determines the flow velocity to the turbine.

Electricity is transmitted onshore through a power

cable inside the tether.

“What makes our technology unique is that we can

extract energy, in a cost-efficient way, from low stream

velocity,” said Arne Quappen, Development Manager,

Minesto. “Our competitors use tidal streams that

are habitually 2.5 meters/second (8.2 feet/second),

whereas we can use tidal streams between 1.5 and

2 meters/second." Another advantage of our system,

compared to our competition, is that their installations are bigger,

heavier and more difficult to install.

” he said.

The technology developed by Minesto is lightweight and

small compared to other tidal solutions, resulting in

reduced costs in material, transport, installation, service,

maintenance and dis assembly."

“We have to compete with other more established

energy sources such as coal or nuclear,” Quappen

said. “The fact that we are not as established as

traditional energy producers is a tough challenge and

one that we have to meet by improving the reliability and

cost- effectiveness of our solutions.”

Designing energy-producing underwater

kites with CATIA PLM Express

Minesto uses CATIA to design innovative tidal energy solutions. The flexibility

and rapidity with which it can create its designs enables Minesto to show potential

customers design variations based on their requirements. Compared to its previous

CAD system, model size is no longer a problem, allowing Minesto to work on

complex models and assemblies of its products.

Arne Quappen

Development Manager, Minesto

With CATIA, we can work on more complex

models and assemblies with all the related

details. Model size is no longer a problem.

Catering to the nee ds of potential

customers

Minesto is currently developing and testing prototypes

of its solution before going to production. “Our objective

is to create a robust design of our kite that we can then

adapt to the needs of our customers,

” Quappen said.

“As a development company we are in discussion with

potential customers to collect their requirements and to

implement them in our commercial products.”

In 2010, Minesto chose CATIA PLM Express from

Dassault Systèmes for its 3D design work and for

drawing production. “Our previous solution lacked

the design precision and flexibility we needed,”

Quappen said. “During this initial product development

phase, it is important for us to create

different design variations quickly and to

show them to potential customers before

converging on the right design. With

CATIA, as opposed to our previous

solution, we can work on more complex

models and assemblies with all the

related details. Model size is no longer a

problem.”

Semcon, a Dassault Systèmes’ partner,

helped Minesto implement CATIA

provided training and consulting services.

“Semcon’s industry know-how and

extensive knowledge of CATIA accelerated

our learning curve

,” Quappen said.

Minesto, based in Gothenburg, Sweden, is a

spin-off of the Saab Group. Formed in 2007,

the company develops technology for a new

type of tidal power plant. After validating

the cost-effectiveness and viability of its

designs, Minesto was chosen by the Carbon

Trust to participate in its Marine Energy

Accelerator program. Minesto was recently

granted £350,000 from the Carbon Trust to

deploy the first prototype of its Deep Green

underwater kite. Carbon Trust´s programs

support those companies that are most

promising in the development of alternative

energy solutions.

Minesto

By Dora Laîné]

For more information:

www.minesto.com

Sunday, 4 March 2012

Wednesday, 29 February 2012

Transformerless 12V DC Power Supply

Electric Shock Hazard. In the UK,the neutral wire is connected to earth at the power station. If you touch the "Live" wire, then depending on how well earthed you are, you form a conductive path between Live and Neutral. DO NOT TOUCH the output of this power supply. Whilst the output of this circuit sits innocently at 12V with respect to (wrt) the other terminal, it is also 12V above earth potential. Should a component fail then either terminal will become a potential shock hazard.

Below is a project by Ron J, please heed the caution above and Ron's design notes.

If you are not experienced in dealing with it, then leave this project alone.Although Mains equipment can itself consume a lot of current, the circuits we build to control it, usually only require a few milliamps. Yet the low voltage power supply is frequently the largest part of the construction and a sizeable portion of the cost.

This circuit will supply up to about 20ma at 12 volts. It uses capacitive reactance instead of resistance; and it doesn't generate very much heat.The circuit draws about 30ma AC. Always use a fuse and/or a fusible resistor to be on the safe side. The values given are only a guide. There should be more than enough power available for timers, light operated switches, temperature controllers etc, provided that you use an optical isolator as your circuit's output device. (E.g. MOC 3010/3020) If a relay is unavoidable, use one with a mains voltage coil and switch the coil using the optical isolator.C1 should be of the 'suppressor type'; made to be connected directly across the incoming Mains Supply. They are generally covered with the logos of several different Safety Standards Authorities. If you need more current, use a larger value capacitor; or put two in parallel; but be careful of what you are doing to the Watts. The low voltage 'AC' is supplied by ZD1 and ZD2.

The bridge rectifier can be any of the small 'Round', 'In-line', or 'DIL' types; or you could use four separate diodes. If you want to, you can replace R2 and ZD3 with a 78 Series regulator. The full sized ones will work; but if space is tight, there are some small 100ma versions available in TO 92 type cases. They look like a BC 547. It is also worth noting that many small circuits will work with an unregulated supply. You can, of course, alter any or all of the Zenner diodes in order to produce a different output voltage. As for the mains voltage, the suggestion regarding the 110v version is just that, a suggestion. I haven't built it, so be prepared to experiment a little.

I get a lot of emails asking if this power supply can be modified to provide currents of anything up to 50 amps. It cannot. The circuit was designed to provide a cheap compact power supply for Cmos logic circuits that require only a few milliamps. The logic circuits were then used to control mains equipment (fans, lights, heaters etc.) through an optically isolated triac. If more than 20mA is required it is possible to increase C1 to 0.68uF or 1uF and thus obtain a current of up to about 40mA. But 'suppressor type' capacitors are relatively big and more expensive than regular capacitors; and increasing the current means that higher wattage resistors and zener diodes are required. If you try to produce more than about 40mA the circuit will no longer be cheap and compact, and it simply makes more sense to use a transformer

Below is a project by Ron J, please heed the caution above and Ron's design notes.

MAINS ELECTRICITY IS VERY DANGEROUS.

If you are not experienced in dealing with it, then leave this project alone.Although Mains equipment can itself consume a lot of current, the circuits we build to control it, usually only require a few milliamps. Yet the low voltage power supply is frequently the largest part of the construction and a sizeable portion of the cost.

This circuit will supply up to about 20ma at 12 volts. It uses capacitive reactance instead of resistance; and it doesn't generate very much heat.The circuit draws about 30ma AC. Always use a fuse and/or a fusible resistor to be on the safe side. The values given are only a guide. There should be more than enough power available for timers, light operated switches, temperature controllers etc, provided that you use an optical isolator as your circuit's output device. (E.g. MOC 3010/3020) If a relay is unavoidable, use one with a mains voltage coil and switch the coil using the optical isolator.C1 should be of the 'suppressor type'; made to be connected directly across the incoming Mains Supply. They are generally covered with the logos of several different Safety Standards Authorities. If you need more current, use a larger value capacitor; or put two in parallel; but be careful of what you are doing to the Watts. The low voltage 'AC' is supplied by ZD1 and ZD2.

The bridge rectifier can be any of the small 'Round', 'In-line', or 'DIL' types; or you could use four separate diodes. If you want to, you can replace R2 and ZD3 with a 78 Series regulator. The full sized ones will work; but if space is tight, there are some small 100ma versions available in TO 92 type cases. They look like a BC 547. It is also worth noting that many small circuits will work with an unregulated supply. You can, of course, alter any or all of the Zenner diodes in order to produce a different output voltage. As for the mains voltage, the suggestion regarding the 110v version is just that, a suggestion. I haven't built it, so be prepared to experiment a little.

I get a lot of emails asking if this power supply can be modified to provide currents of anything up to 50 amps. It cannot. The circuit was designed to provide a cheap compact power supply for Cmos logic circuits that require only a few milliamps. The logic circuits were then used to control mains equipment (fans, lights, heaters etc.) through an optically isolated triac. If more than 20mA is required it is possible to increase C1 to 0.68uF or 1uF and thus obtain a current of up to about 40mA. But 'suppressor type' capacitors are relatively big and more expensive than regular capacitors; and increasing the current means that higher wattage resistors and zener diodes are required. If you try to produce more than about 40mA the circuit will no longer be cheap and compact, and it simply makes more sense to use a transformer

Transformerless 5V DC Power Supply

Transformerless 5V DC Power Supply

This board takes AC mains input from 100V to

250V AC and output regulated +5V DC providing

current up to 50mA. Great for running small

and almost zero heat generation.

In most non-battery applications, the power to the

mounted transformer, which is then rectified,

filtered and regulated. In most applications, this

method of generating the regulated voltage is

cost effective and can be justified. However,

there are applications where the main controller

and low voltage is not required by other

components except the microcontroller in

application. In these instances, the cost of the

transformer becomes the sizable cost factor in

the system. For example, most fire alarms &

round the clock monitoring alarms are powered

this way.

Transformerless power supplies, thus, have a distinct advantage in cost as well as in size. The

disadvantages of using a transformerless power supply are low current supply and no isolation from

The microcontrollers usually draw a maximum of 20 mA, even at the highest frequency and voltage

of operation, therefore low current availability is not an issue. The main disadvantage of

transformerless supplies is that they don't offer isolation from the HV line.

One down side of this circuit that it is not isolated from mains so it should not be used in

applications requiring touch of any contact from user. If any part even though +5V side is touched it

would cause shock to the user. Please be careful about touching when using it during experiments

or final applications.

Warning! An electrocution hazard exists during experimentation with transformerless circuits that

interface to AC mains wall power. There is no transformer for power-line isolation in the circuit, so

the user must be very careful and assess the risks from line-transients in the user’s application.

An isolation transformer should be used when probing the circuit during experimentation.

Monday, 30 January 2012

WATER-LEVEL CONTROLLER

K.P. VISWANATHAN

Here is a simple, automatic waterlevel

controller for overhead tanks

that switches on/off the pump motor

when water in the tank goes below/

above the minimum/maximum level. The

water level is sensed by two floats to operate

the switches for controlling the pump

motor.

Each sensors float is suspended from

above using an aluminium rod. This arrangement

is encased in a PVC pipe and

fixed vertically on the inside wall of the

water tank. Such sensors are more reliable

than induction-type sensors. Sensor

1 senses the minimum water level, while

sensor 2 senses the maximum water level

(see the figure).

Leaf switches S1 and S2 (used in tape

recorders) are fixed at the top of the sensor

units such that when the floats are

lifted, the attached 5mm dia. (approx.) aluminium

rods push the moving contacts

(P1 and P2) of leaf switches S1 and S2

from normally closed (N/C) position to

normally open (N/O) position. Similarly,

when the water level goes down, the moving

contacts revert back to their original

positions.

Normally, N/C contact of switch S1 is

connected to ground and N/C contact of

switch S2 is connected to 12V power supply.

IC 555 is wired such that when its

trigger pin 2 is grounded it gets triggered,

and when reset pin 4 is grounded it gets

reset. Threshold pin 6 and discharge pin 7

are not used in the circuit.

When water in the tank goes below

the minimum level, moving contacts (P1

and P2) of both leaf switches will be in

N/C position. That means trigger pin 2

and reset pin 4 of IC1 are connected to

ground and 12V, respectively. This triggers

IC1 and its output goes high to

energise relay RL1 through driver transistor

SL100 (T1). The pump motor is

switched on and it starts pumping water

into the overhead tank if switch S3 is ‘on.’

As the water level in the tank rises,

the float of sensor 1 goes up. This shifts

the moving contact of switch S1 to N/O

position and trigger pin 2 of IC1 gets connected

to 12V. This doesn’t have any impact

on IC1 and its output remains high

to keep the pump motor running.

As the water level rises further to reach

the maximum level, the float of sensor 2

pushes the moving contact of switch S2

to N/O position and it gets connected to

ground. Now IC1 is reset and its output

goes low to switch the pump off.

As water is consumed, its level in the

overhead tank goes down. Accordingly,

the float of sensor 2 also goes down. This

causes the moving contact of switch S2 to

shift back to NC position and reset pin 4

of IC1 is again connected to 12V. But IC1

doesn’t get triggered because its trigger

pin 2 is still clamped to 12V by switch S1.

So the pump remains switched off.

When water level further goes down

to reach the minimum level, the moving

contact of switch S1 shifts back to N/C

position to connect trigger pin 2 of IC1 to

ground. This triggers IC1 and the pump is

switched on.

The float sensor units can be assembled

at home. Both the units are identical, except

that their length is different. The depth

of the water tank from top to the outlet

water pipe can be taken as the length of the

minimum-level sensing unit. The depth of

the water tank from top to the level you

want the tank to be filled up to is taken as

the length of the maximum-level sensing

unit. The leaf switches are fixed at the top

of the tank as shown in the figure.

Each pipe is closed at both the ends by

using two caps. A 5mm dia. hole is drilled

at the centre of the top cap so that the

aluminium rod can pass through it easily to

select the contact of leaf switches. Similarly,

a hole is to be drilled at the bottom

cap of the pipe so that water can enter the

pipe to lift the float.

When water reaches the maximum

level, the floats should not go up more

than the required distance for pushing

the moving contact of the leaf switch to

N/O position. Otherwise, the pressure on

the float may break the leaf switch itself.

The length of the aluminium rod is to be

selected accordingly. It should be affixed

on the metal/thermocole float using some

glue (such as Araldite).

Subscribe to:

Comments (Atom)